As an expert in the manufacture of dip coaters (dip coating equipment), SDI has given shape to the needs of overseas customers.

We have received high evaluations from various countries, mainly in Asia, and have many delivery records.

SDI's dip coater is characterized by its easy operation and maintenance. Easy operation is possible with the touch panel method. In addition, daily maintenance can be easily performed.

The dip coater has a wide range of processing speeds, from 1 nm/sec to 200 mm/sec. Uniform thin film formation is possible due to speed unevenness and low vibration.

At SDI, we make proposals that match the needs and budgets of our customers. Please contact us for special orders and customize

Desktop device for experiments / research / development Specifications /

The most optimum dipcoater for Super Slow Action Speed Dip Coat (Dip Coating) is this dipcoater (Dip Coating Machine) which enabled to adjust working angle by the controlling of working two-axes & Θ angle and diagonal raise-up.

This is the dipcoater (Dip Coating Equipment) to be able to make Dip Coating (Dip Coat) for Glass, Acrylic,

Copper Foil and Tube-formed Materials at the super low-speed in nano-unit (variableness every 1nm).

This is suitable to form the Thin Film of the nano-level, the Opal Film and to generate the Particle Array, etc.

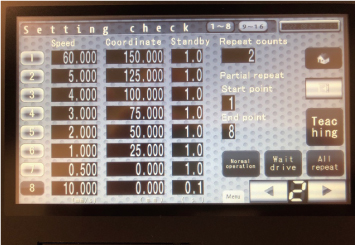

That operation adopts a touch panel method. The Operations for Bi-axial Synchronization also Single-axial alone driving both can be done easily.

On the touch panel, Operations for the setting of the Speed Changing Points (up to 16 points as max), the Speed Changes (by 1nm unit), the Repetition Movements and the Memory of the Movement Patterns (up to 8 patterns as max) can be done easily. This system was developed under kind direction from Hirao-Laboratory of Kyoto University.

As the indication of Japanese or English is one-touch change, so it is the most suitable for the place where researchers of foreigners exist.

| Main Specifications | |

| Stroke | Z-axis 150 mm, X-axis 150 mm |

| Minimum Speed (Min.) | 1nm/sec. |

| Maximum Speed (Max) | 60mm/sec. |

| perating Method | Touch Panel |

| Screen Indication Language | Japanese / English |

| Number of designation points for Transaction Speeds |

16 Points |

| Number of designation points for Stop Positions |

16 Points |

Linear Driving Mode means that stopping time is zero (0) sec. at the changing speed.

Manual Driving Mode means that it is doing rise / drop driving (another setting for the rise speed and the drop speed) at one set speed.

Desktop device for experiments / research / development Specifications /

This is the optimum dipcoater for Super Low Speed Dip Coat (Dip Coating) of our sale results the 1st place. Variable range of the speed changing is from 1 nm/sec. to 60 mm/sec

This dipcoater is available to Dip Coat for Glass, Acrylic, Copper Foil and Tube-like Materials by Nano Unit Speed (variableness every um).

It is suitable for Separation Film Generation, Particle Array and the Film Thickness Formation in the nano-level. The operation adopts a Touch Panel Method.

On the touch panel, Operations for the setting of the Speed Changing Points (Max 16 points), the Speed Changes (by 1nm unit), the Repetition Movements and the Memory of the Movement Patterns (Max 8 patterns) can be done easily. This system was developed under kind direction from “The National Institute of Advanced Industrial Science and Technology (AIST) Tsukuba”. As the indication of Japanese or English is one-touch change, so it is the most suitable for the place where researchers of foreigners work.

| Main Specifications | |

| Stroke | 150mm (Up to 800mm is available as an option.) |

| Minimum Speed (Min.) | 1nm/sec. |

| Maximum Speed (Max) | 60mm/sec. |

| perating Method | Touch Panel |

| Screen Indication Language | Japanese / English |

| Number of designation points for Transaction Speeds |

16 Points |

| Number of designation points for Stop Positions |

16 Points |

| Number of designation points for Stopping Time |

16 Points |

| Consecutive Driving Mode | Equipped |

| Manual Driving Mode | Equipped |

| Number of Memorized Programs | 8 Programs |

| Monitoring Function: Present Speed | Equipped |

| Monitoring Function: Present Position | Equipped |

| Residual Time of Monitoring | Equipped |

| Repetition Driving | Equipped |

| Standard Clip | Material: Polypropylene (PP) |

| Utility | AC100V,250VA |

| Maximum Weight Capacity | 1kg |

| Maximum Processing Size (mm) | H:150mm |

| Linear Driving Mode | Not Equipped |

| Equipment Dimension (mm): not including projections | W:350 D:256 H:507 |

| Control Box Dimension (mm) : not including projections | W:300 D:285 H:163 |

Linear Driving Mode means that stopping time is zero (0) sec. at the changing speed.

Manual Driving Mode means that it is doing rise / drop driving (another setting for the rise speed and the drop speed) at one set speed.

The numerical value shown in ( ) of Minimum Speed and Maximum Speed columns can be operated by conversion switch.

Desktop device for experiments / research / development Specifications /

This is the dipcoater of popularity in Desk Top Type Dip Coat (Dip Coating) Equipments. This is the Device to form both faces of the thin films at one time with dipping and raising-up the working object clipped by hanger into / from coating liquid in a tank.

This is the dipcoater can do the Dip Coat for small Glass, Acrylic, Copper Foil and Tube-like Materials by mm Unit Speed (variableness every 0.1 mm/sec.). This is the most suitable for the simple test on the desk top.

By the touch panel, Operations of the Speed Changing Points, the Speed Changes and the Memory of the Movement Patterns can be done.

| Stroke | 300mm |

| Minimum Speed (Min.) | 0.1mm/sec. |

| Maximum Speed (Max) | 60mm/sec. |

| Operating Method | Touch Panel |

| Screen Indication Language | Japanese / English |

| Number of designation points for Transaction Speeds | 8 Points |

| Number of designation points for Stop Positions | 8 Points |

| Number of designation points for Stopping Time | 8 Points |

| Consecutive Driving Mode | Equipped |

| Manual Driving Mode | Equipped |

| Number of Memorized Programs | 2 Programs |

| Monitoring Function: Present Speed | Equipped |

| Monitoring Function: Present Position | Equipped |

| Monitoring Function: Residual Time | Equipped |

| Repetition Driving | Not Equipped |

| Standard Clip | Material: Stainless Steel |

| Utility | AC100V,250VA |

| Weight Capacity | 1kg |

| Maximum Processing Size (mm) | H:300mm |

| Linear Driving Mode | Not Equipped |

| Equipment Dimension (mm): not including projections | W:430 D:476 H:815 |

| Control Box Dimension (mm) : not including projections | W:300 D:285 H:163 |

Linear Driving Mode means that stopping time is zero (0) sec. at the changing speed.

Manual Driving Mode means that it is doing rise / drop driving (another setting for the rise speed and the drop speed) at one set speed.

Desktop device for experiments / research / development Specifications /

This device is Portable Type dipcoater which carrying around is simple & easy. It is the optimum dipcoater in low cost for simple Dip Coats (Dip Coatings) without changing speed.

Desk Top Type dipcoater with low-cost correspondence

This is the Dip Coating (Dip Coat) Device of

1. PC Unnecessary

2. Easy Carrying Around

3. Specifications of Low Cost Performance

| Stroke | 150mm |

| Minimum Speed (Min.) | 1um/sec. |

| Maximum Speed (Max) | 20mm/sec. |

| Operating Method | Touch Panel |

| Screen Indication Language | Japanese |

| Number of designation points for Transaction Speeds | Not Equipped |

| Number of designation points for Stop Positions | Not Equipped |

| Number of designation points for Stopping Time | Not Equipped |

| Consecutive Driving Mode | Not Equipped |

| Manual Driving Mode | Not Equipped |

| Number of Memorized Programs | Not Equipped |

| Monitoring Function: Present Speed | Not Equipped |

| Monitoring Function: Present Position | Not Equipped |

| Monitoring Function: Residual Time | Not Equipped |

| Repetition Driving | Not Equipped |

| Standard Clip | Material: Polypropylene (PP) |

| Utility | AC100V,250VA |

| Weight Capacity | 1kg |

| Maximum Processing Size (mm) | H:150mm |

| Linear Driving Mode | Not Equipped |

| Equipment Dimension (mm): not including projections | W:410 D:210 H:495 |

2 tank dip

2-axis synchronous operation

θ-axis operation

DT-0001-N1

MD-0408-N1

DT-0303-N1